Inspiration Into Action

Several years ago while attending SXSW Interactive I ran across a vendor in the street giving away what I thought was hard, plastic toys. In reality, they were 3D-printed sugar dessert sculptures. You could either eat them raw as many were doing or you could choose to dump them in your coffee as I did. While I can’t say that the flavor actually enhanced my coffee (it essentially just turned it into a clumpy mess and I had to throw it away), the idea of actually creating something like what he showed me was amazing and stuck with me well beyond the encounter.

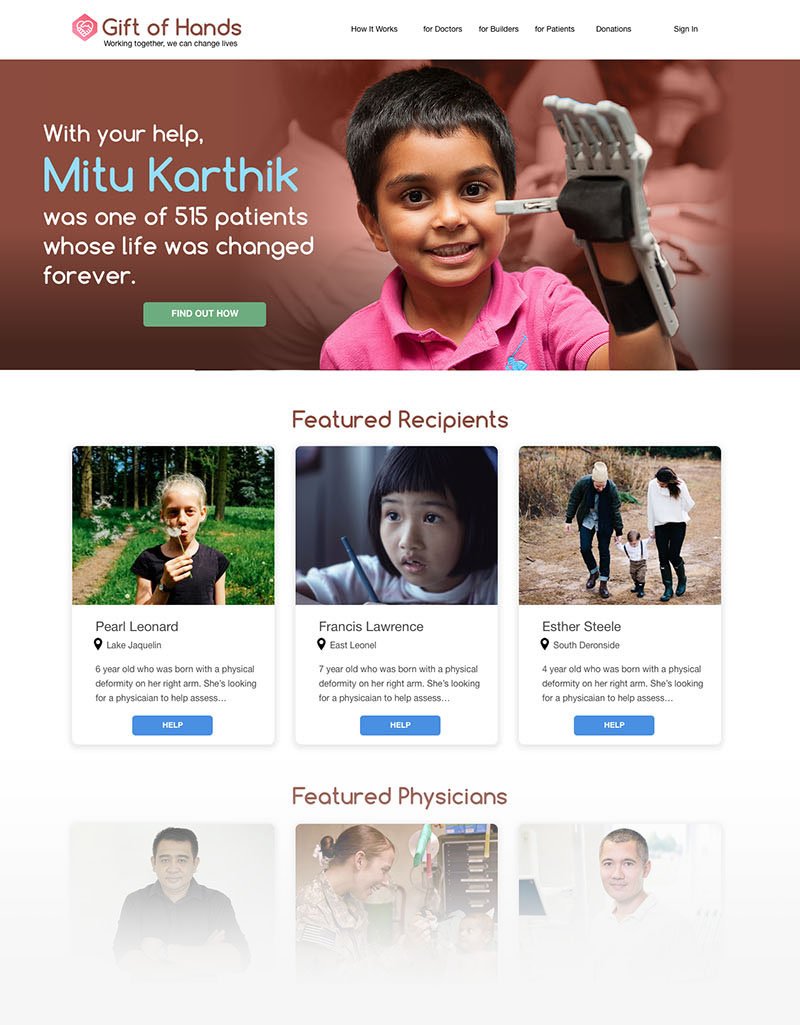

Several months later I would have the opportunity to work on a project that would have me contemplating 3D printing in a tangible sense. More on this later.